Centenary celebrations this year prompted Trinity Hall’s Vasant Kumar to look back at the history of a department that has supported his ground-breaking research into environmentally friendly battery technology and water purification. Professor Kumar, Director of Studies and Fellow in Natural Sciences at Trinity Hall, looks at the Department of Materials Science and Metallurgy at the University of Cambridge and tells us how he is proud of his work representing the Materials Science curriculum and research which is underpinned by ecological concerns.

The Department of Materials Science at University of Cambridge is a world-leading centre for research and teaching in the area of Materials Science & Metallurgy. Metallurgy – the precursor to Materials – was born in Sidney Sussex College in the 19th century and then launched by the Goldsmiths’ Company in the New Museum site at the heart of the City Centre in 1920. Only recently, beginning from 2013-14, did the Department move to a new home on the rapidly developing West Cambridge site.

The Department of Materials Science excels in a broad range of research areas; from at-scale processing of metals and composites to nanotechnology, device materials, materials chemistry, bio-medical materials and modelling from atomic to bulk scale. The rigorous research in the Department underpins and reflects the increasingly popular four-year undergraduate Materials curriculum.

The basic understanding of materials begins at the deepest level of structure deduced by interaction of matter with electromagnetic radiation such as X-ray or UV light and by visualising the details under microscopes often at such colossal magnifications that “seeing is believing” acquires a whole new meaning.

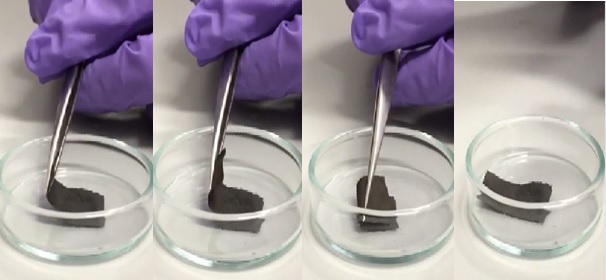

An example is shown below, where a remarkably useful material containing over 80% by weight of very brittle oxide can be bent elastically and the shape fully recovers.

Nanoparticles of oxide-carbon composite containing over 80 wt% of brittle oxide supported by only 20 wt% carbon which can be fully folded without breaking_Cheng-Yen Lao, MPhil T

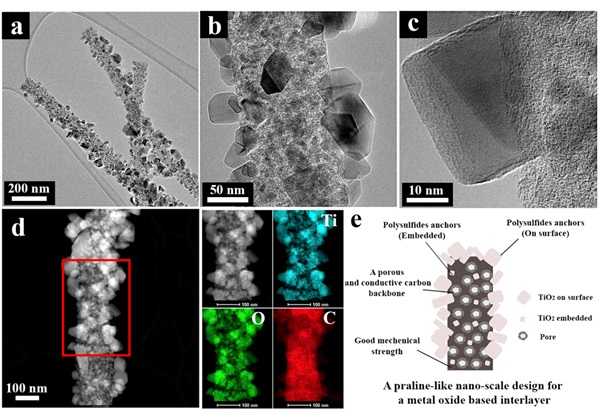

The material is held together by nanoparticles of carbon with nano-oxide embedded inside and outside the fibrous composite, as shown below. Such materials are relevant for making foldable ceramic sensors, batteries and many other devices.

Electron Microscopy images for investigating the nano-scale design of materials_Cheng-Yen Lao, MPhil Thesis, University of Cambridge

A vital message of Materials Science and Metallurgy is that micro- and nano- structures determine the properties and applications of the materials. The challenges addressed at the cutting-edge by the Department cover an impressive innovative canvas including aerospace materials, information and communications technology, materials discovery, materials for energy and sustainability, novel designs and processing, and healthcare materials. The Department also looks at advanced, cutting edge methods for characterising the properties of materials and devices.

The new building in West Cambridge is inspired by the great importance of structure of materials at micro- and nano-levels. The Outerwall is a recessed structure containing projecting bricks for depicting patterns resembling microstructure of materials, taught and researched within the building (main article image).

The first event to celebrate the Centenary Year was launched on 22 October 2020, both looking back proudly on the historic achievements in the subject and showcasing the exciting future prospects. For other events that will follow, watch the space via the link: www.msm.cam.ac.uk

I am proud to be a Fellow of Trinity Hall in Natural Sciences representing the Materials Science curriculum and the research area underpinned by the drive to be more ecologically aware in development of new materials and how we can apply them to real life.

Through my own research work and of research undertaken in my research group, I actively promote real-world applications and collaborate widely with stakeholders globally to make this happen.

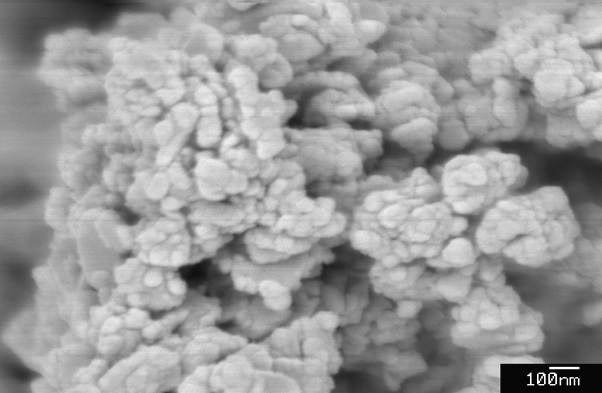

One recent example of industrial impact from my own research in our group relates to the development of a new environmentally clean-process for recovering electro-active paste material from automotive and off-grid renewable storage batteries. We can then re-use this in making new batteries, eliminating waste and creating a ‘circular economy’ for these products. Several other research centres and universities have followed this lead by setting up collaborative research with Cambridge. Based upon a number of successful technical and financial evaluations by the industry, Cambridge Enterprise has licensed the technology to iQ International, a US/Swiss multinational company with a pilot plant in the UK Branch – Ever Resources Ltd. This is a “disruptive innovation”, in comparison with existing methods. Not only is it efficient, cheaper and clean, but it can also directly produce the essential battery ingredient with an improved microstructure described as porous nano-crystalline (image below), which gives new batteries a 30% greater energy density output and a 50% longer battery life in laboratory tests, while reducing the carbon footprint by 85%, noxious gas emissions by 99% and net wastes by 90%. Expression of interests for uptake of technology is widespread globally.

Nanocrystalline product after recovering active materials from a spent battery

I have also participated in founding companies in order to take forward the research outcomes into applications with licences from Cambridge Enterprises. Over the years I have researched into the area of chemical sensing for environmental monitoring, air pollution mapping, process and quality control, safety in domestic, public and industrial activities and prevention of accidents and disasters. Two start-up companies – EMC Ltd in the UK and MNST Pvt Ltd in India – are manufacturing and selling products globally. Another patented technology relates to using solar light activated materials for destroying pollutants and microbes in water and in the atmosphere. Our research group has taken this product for trials with local communities and academic researchers in Tanzania and Ghana. Two of our PhD students have set up companies (CamSES Ltd. And Majico as a social enterprise) to advance this technology in developing countries.